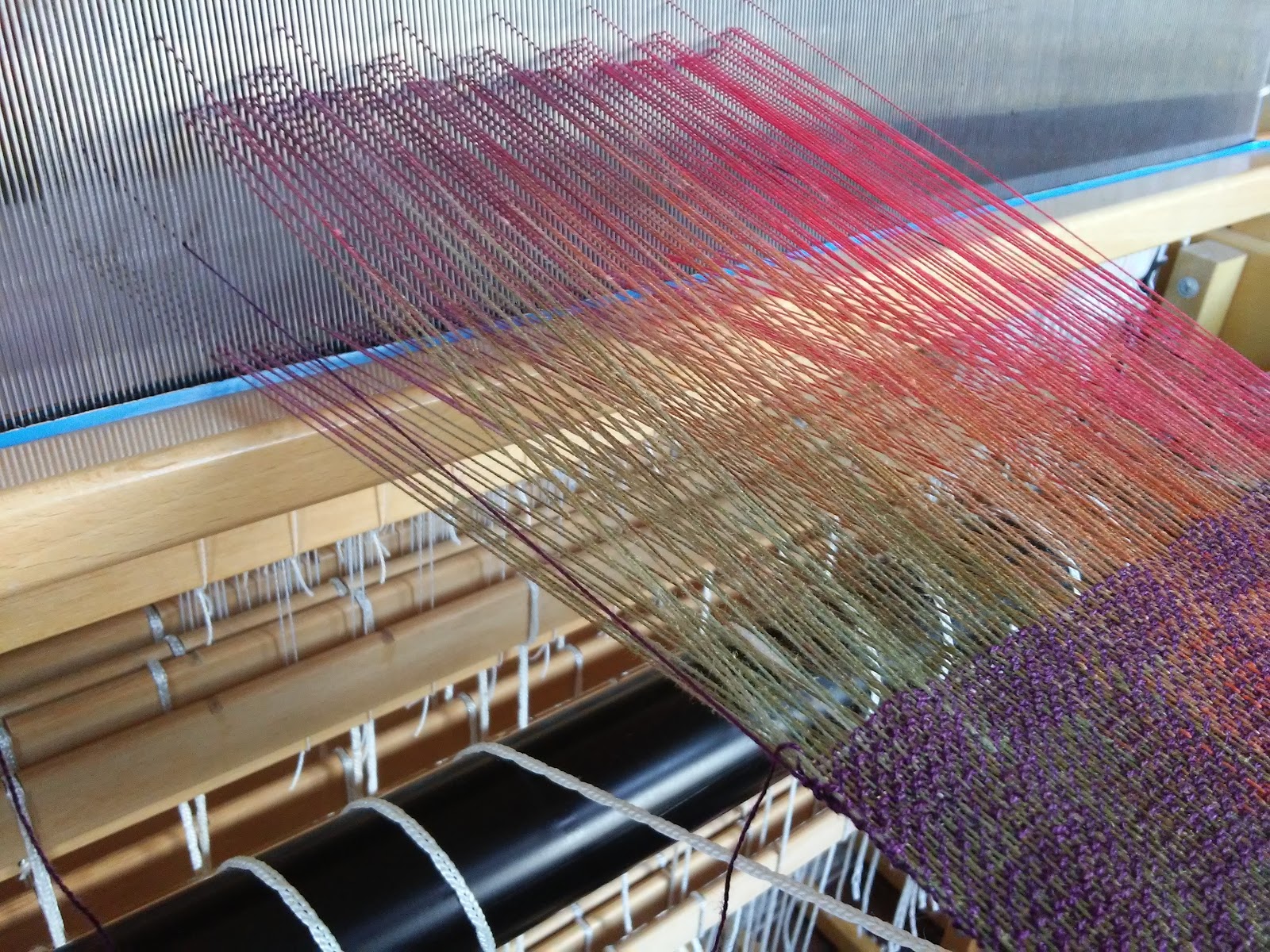

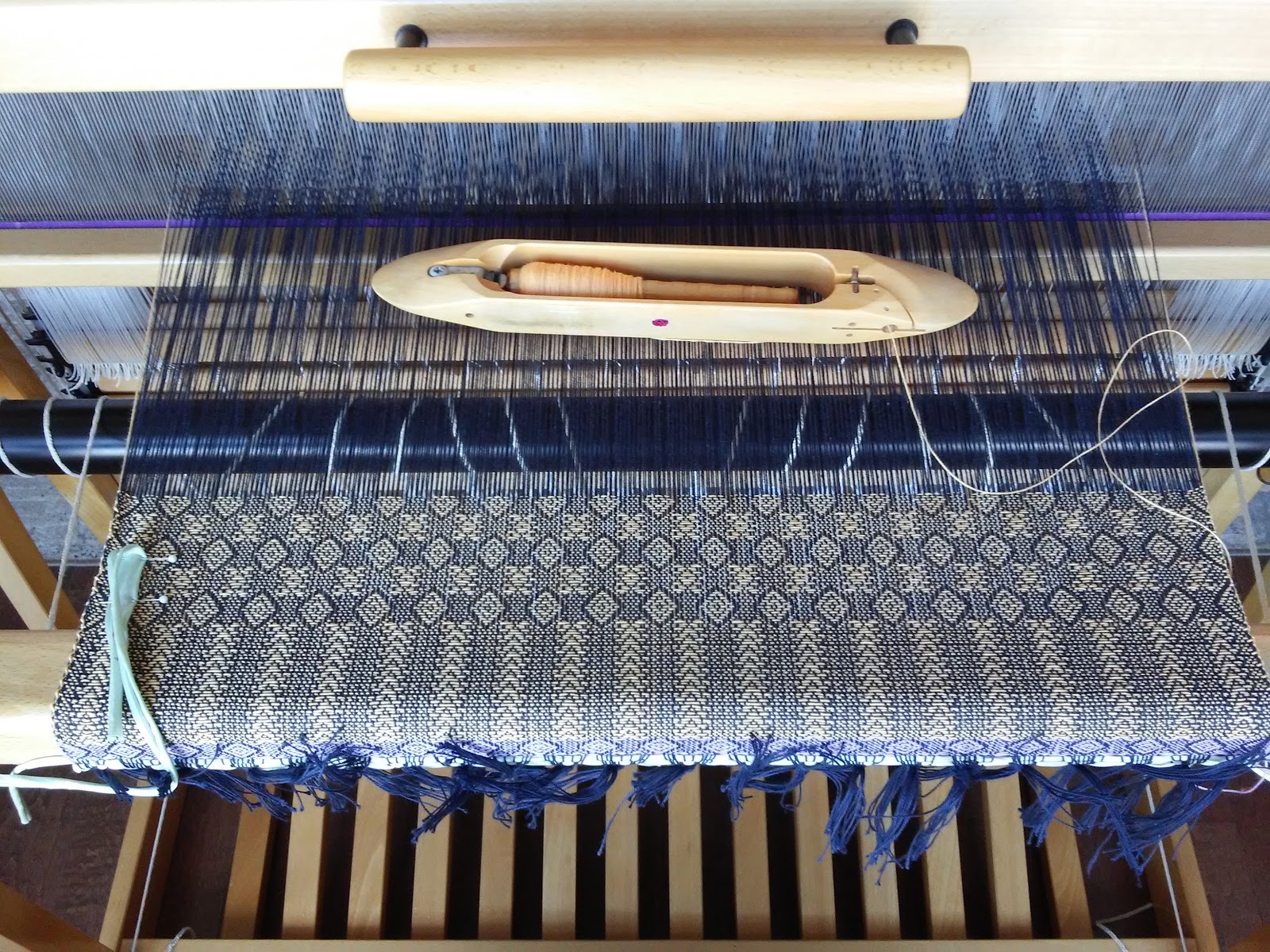

I can’t believe its been a month since the last post! I’ve finished weaving the autumn leaves silk scarf. To remind you the warp of the scarf was hand dyed in orange, plum, moss, bronze brown and scarlet and the weft is eggplant purple Tencel. The pattern is a personal favourite, it is a network twill that kind of looks like leaves.

The finished scarf is quite lovely, the bright hit of the orange really stands out. I think that a scarf needs to be bright and cheerful against a dark winter coat. For Sale.We went on the first botany walk for the year and while there wasn’t much to see yet, we did some identifying of trees by their bark, there was some hints of spring. These are fawn lilies (Erythronium oregonum) and they are probably blooming now, three weeks later!

In our garden, we’ve add a new raised bed into the vegetable patch. We put it into a difficult corner where the land dips making it hard to plant, but, it is the hottest part of the garden so we don’t want to waste it. We are doing Hügelkultur which is a layering technique for a raised bed. You start with a layer of wood/logs, then compost-able leaves and debris, then compost and lastly top soil. It helps to bulk out the new bed so you aren’t having to buy lots of soil. It is also composting so there will be nutrients available for years as the layers break down. We are still in the process of layering.

The forget me nots (Myosotis scorpioides) are blooming, they have such a pretty delicate bloom. And the lilacs are starting to leaf out and the blooms are just starting to form. It is hard to believe that it is only the beginning on April. I think that we are almost two weeks earlier than normal for spring here on our part of Vancouver Island.

In one of the Japanese maple trees there are two branches that are crossing but they are both integral for the shape of the tree. So we are pulling one branch down using a piece of string tied to a rock, it is working but it does look like the tree has a pet rock that it is taking for a very, very slow walk! Every time I walk past this tree it makes me giggle.